BLT products are made with advanced machines recognized around the world. They stand out for their precise manufacturing and strong durability, able to work in extreme conditions - from freezing polar cold to very high heat and even underwater.

Founded in 2002, BEILITE Machinery Co., Ltd. has been guided by its development philosophy of "Quality Changes the Future", and focusing on the R&D, production and service of high-end hydraulic breakers.

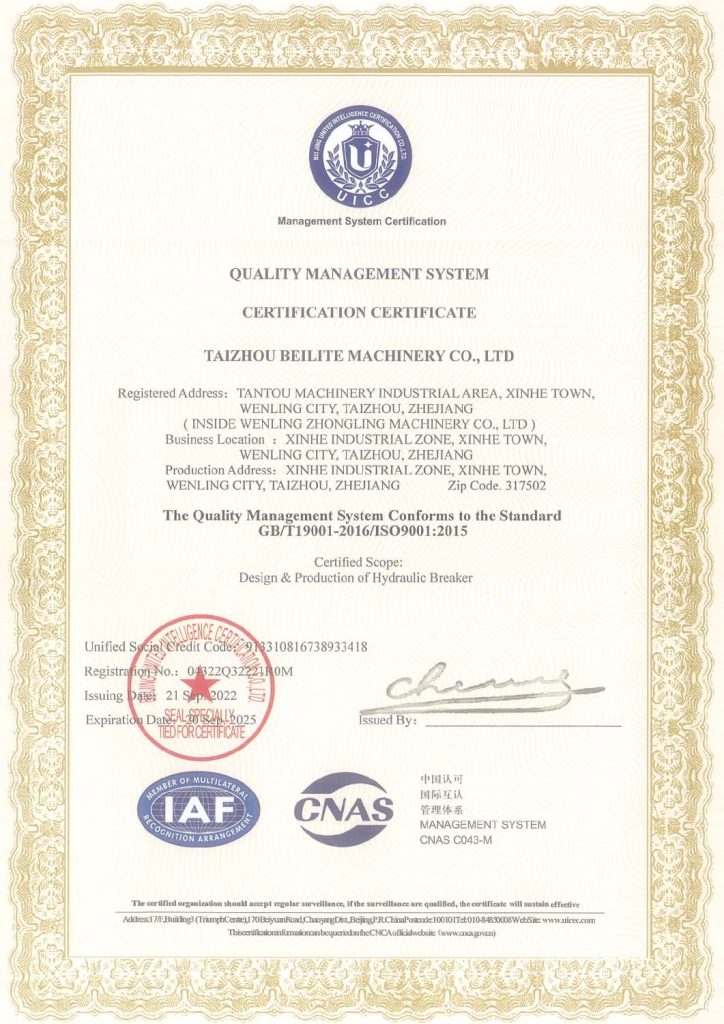

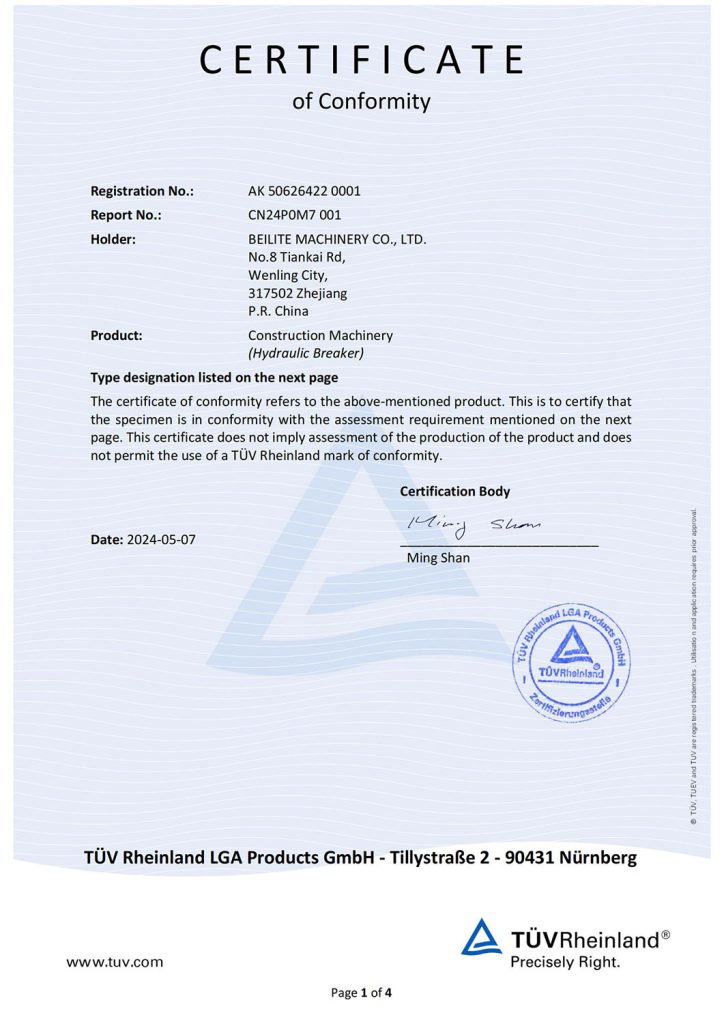

As a Chinese National High-Tech Enterprise, BEILITE works to implement Intelligent Manufacturing Strategy, and drives its rapid development with continuous innovation capabilities. Breaking through key hydraulic breaker manufacturing technologies, BEILITE successfully developed the first Chinese heavy-duty hydraulic breaker and first underwater hydraulic breaker. BEILITE holds hundreds of international leading technology patents, being certified through the three systems of quality, environment, occupational health, as well as the EU CE safety certification.

Sound Sur-pressed Range: The sound sur-pressed range is widely used in international markets and highly recommended by clients. Its key advantage is noise reduction, making it ideal for mining, urban construction, high altitude usage, and tunnel operations where low noise levels are required.

Top-Mounted Range: The top-mounted range features a heavy-impact design suitable for multiple vertical strike operations, especially in underwater environments. Its flexibility and durability make it ideal for tunnel work, underwater tasks, and building demolition projects.

Side-Mounted Range: Popular in domestic markets, the side-mounted breaker is lightweight, easy to maintain, and efficient. With fewer components than box and top-mounted types, it offers a durable, low-maintenance design. Its low installation point allows precise control with an excavator, making it ideal for mining, asphalt removal, and concrete or rock breaking. It also enables direct sweeping of debris for added convenience.

30+ member innovation driven R&D team.

$2M annual R&D budget drives innovation in industry core technologies.

70+ internationally leading precision machines (DMG, MORI, DOOSAN, etc.) ensure component accuracy meets design specs.

State-of-the-art testing equipment guarantees every product passes comprehensive precision checks.